3 53 4 54 5 55 6 56 7 57 8 58 9 59 10 60 11 61 12 62 13 63 14 64 15 65 16 66 17 67 18 68 19 69 20 70 21 71 22 72 23 73 24 74 25 75. The skirt thickness should be such that under the worst combination of wind and dead weight loading the following design criteria are not.

Pressure Vessel Skirt Sizing Boiler And Pressure Vessel Engineering Eng Tips

F Average Skirt Temperature T1 F r0-012811.

. Dead weight of the vessel. Any smooth figure of revolution if R 2 is less than infinity Stress and Deflection Equation and Calculator. Whether PV elite does not calculate skirt thickness please let me know.

The various vessel-supporting methods are discussed. For more informations and more complete calculations please check handbook of pressure vessel design for EMOSS Procedure 3-9. Wednesday October 21 2009 By.

I also have a program for doing this A key variable that will have an impact on the flow of product outside of a bin is its cohesive strength. The optimization model assumes two stages of different diameters connected through a conical reducer and it has a supporting skirt which can be cylindrical or conical. The expected shape of skirt distortion is briefly.

The ability to add. Skirt thickness calculationsAssociated quiz. The support skirt is a component that operates at elevated temperatures and should be evaluated for a variety of loading conditions including temperature deadload wind and seismic conditions.

W weight of vessel below the level y. Hi Can some one help me to design skirt support for Vertical Pressure Vessels Here is my parameters I have a vessel weight of 150000 daN A height from the tangente line of the bottom head. Sameer 387 dear In PV Elite software if we do any vertical vessel calculation having skirt then in output file ie.

Calculations by CEMA 5th Edition Piotr Kulinowski Ph. The skirt thickness must be sufficient to withstand the dead weight loads and bending moments imposed on it by the vessel. Wind load acting over the vessel.

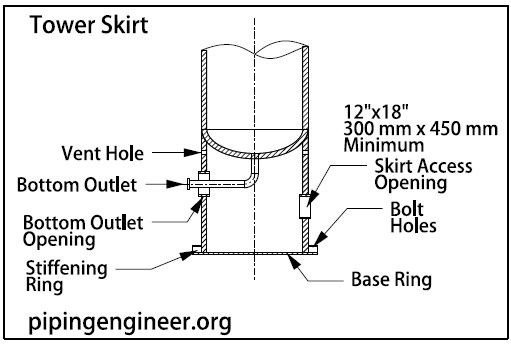

Type of support Type of loading wind loadseismic loadingsnow loading Pressure Vessel Design Formula The basic formula for designing the cylindrical shell is σ PD2t Therefore t PD2σ Where t thickness of the shell P internal pressure D. DESIGN OF SKIRT SUPPORT The skirt height is decided by NPSH requirement of the bottom pump. Support Skirt Openings Piping connections to vertical vessels often require additional piping and an opening cut out of the support skirt.

For a 34 circle skirt this calculator serves as a 34 circle skirt calculator and so on. Support Skirt Design. For skirt CS required data given are lcss 240 Inch 6096 mm Dcss 16984 21496 172832 Inch 4391 mm Values of Design base shear for all the sections of vessel must be between Maximum and Minimum limits calculated as above.

4 meters Here is my Problem Question I have a height with a weight and diameters i want to know the. Tangential Loading Only resultant load. Stainless Steel Allowable Stress f 1350 MPa Top chamber and bottom chamber height 05 m Density of material 8030 kgm3 Number of trays 9 Plate spacing 24 inches 06 m Hole pitch rectangular Diameter.

Skirt support is designed by considering the following loads. Circular pipe sleeves internal projections tilt angles and skirt reinforcing pads can be considered. NPSH P H friction loss vapor pressure NPSH should not be less than 2 to 3 m Skirt height is usually kept about 25 m Bottom of the skirt is welded to bearing plate.

Computers in those days filled whole rooms cost a fortune to run and the engineer had to get all his data punched on cards. Here Vmax and Vmin remain constant for all sections because they dont depend upon height of section. Factors determining the performance of welded skirt supports for vertical process vessels are discussed.

Working pressure 84 kPa 0084 Nmm2 Inside Diameter Di 649 mm Material of construction. Various types of skirts are available such as cylindrical conical lug support on vessel conical support on shell leg support etc. 3 x wall thickness half an inch.

Many researchers have attempted to design and analyze support structure of vessel 1 2. Own weight δ forceunit volume. Average Skirt Temperature Calculation Output Values.

Operating weight of the vessel. Illustrates design procedure for skirt with a numerical problem. Creep design is crucial in high temperature installations.

The objective function is the weight of the shell tiers. In summary design for inputoutput pressure it shows No Calc so why. Seismic Design-Vessel on Skirt page 157 for quick calculations of leg of fillet weld between the skirt and the vessel take the leg of weld equal to 07 of minimum thickness of the skirt and vessel.

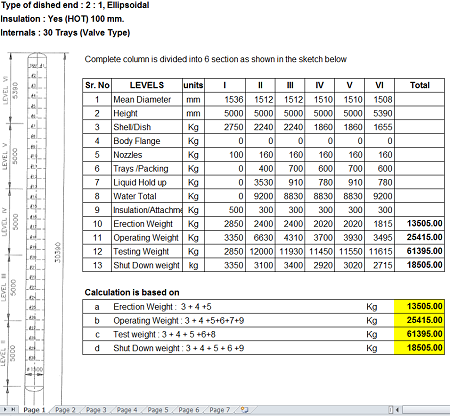

Sample design calculation - skirt support design of vertical column COMBINED STRESS ANALYSIS COMBINED STRESS ANALYSIS TO BE CARRIED OUT FOR FOLLOWING CONDITION A ERECTION CONDITION B OPERATING CONDITION C TESTING CONDITON STRESS SHALL BE CALCULATED INDUCED DUE TO A DEAD WEIGHT B INTERNAL PRESSURE C WIND OR SEISMIC. Which skirt is applicable and need to attach for. MECHANICAL DESIGN OF DISTILLATION COLUMN Given data.

Keep in mind that the smaller the fraction of your skirt is the less fabric youll need. COMPRESS includes the ability to specify and check the adequacy of this commonly encountered design detail. It has formulas for the skirt the base ring the bolting chairs etc etc.

A comprehensive analysis of local stresses with closed-form solutions is presented permitting assessment of expected performance in service on a fatigue basis. Bracket or Lug Supports. Lateral loads by restrained thermal growth of interconnecting pipes.

10 meters an Outside Diameters of the skirt and of the vessel. The importance of thermal effects is emphasized. All head volumetric calculations include a skirt length equal to the minimum value recommended by ASME of.

Assume a thickness of 10 mm for the support skirt and the mean diameter of the support as 425 m. The resultant stresses in the skirt will be. Insulation Coefficient psi K h t 05.

Aside from using this circle skirt calculator or a circle skirt chart you can also perform the calculations manually to find out how much fabric you need. It will not be under vessel pressure. To calculate the skirt thickness all these loads are required to be considered.

The design variables are the thicknesses and lengths of individual shell tiers and the bottom diameter of the supporting skirt. When I designed vessels many many years ago the book Process Equipment Design by Brownell and Young was the bible for skirt design. Tangential top edge support.

Correction Factor Δ T F Δ T 1. Skirt is a cylindrical section that forms the interface to the cylinder or connection flange the wall thickness of which should be at least the same as the vessel to which it is attached. Skirt strength and stability are compromised by all necessary piping and access openings.

Volume Xvi Pressure Vessel Support Skirt Boardman Llc

Skirt Support Vertical Column Pressure Vessel Equations And Calculator

Pressure Vessel Fabrication Vessels Supports Detailing Part 7 Let Sfab Youtube

Design Of Skirt Base Ring And Compression Ring Intergraph Cadworx Analysis

Volume Xvi Pressure Vessel Support Skirt Boardman Llc

Volume Xvi Pressure Vessel Support Skirt Boardman Llc

3d Pressure Vessel Design Software Support Skirt Youtube

Distillation Tower Elevation And Support The Piping Engineering World

0 comments

Post a Comment